Project Description

As the #1 steel producer, the client was involved in providing metal frame structures for the production of modular architectural units. In this project, the R&D/innovation department was exploring the mass production of modular architectural units, as a new product or service offering.

The brief asked us to develop the strategy for modular manufacturing; we were also asked to design an open-innovation platform that would help in co-creating different aspects of the units, customizing it to different needs.

Our solution was to offer a modular production model that could be adapted to different industries – view project details below for more detailed information.

Client

R&D of ArcelorMittal Spain

Applied capabilities

Business Design ~ Innovation Strategy ~ Service Design ~ UX Design

Project Timeline

3 months

Team Members

Juan David León, Mauricio Guillén, Suzanne Balima

Promo video

Research Highlights

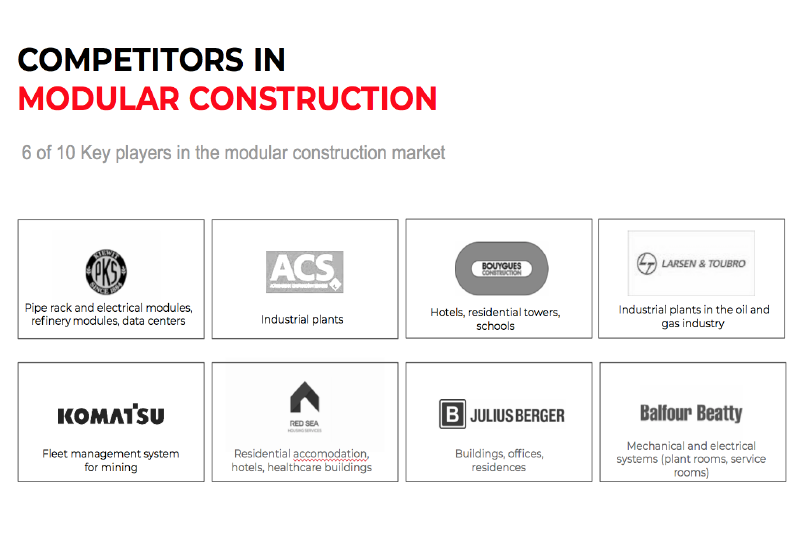

We investigated the key players in the modular construction industry to see which industries they serve, their global reach, as well as how they achieve their competitive advantage.

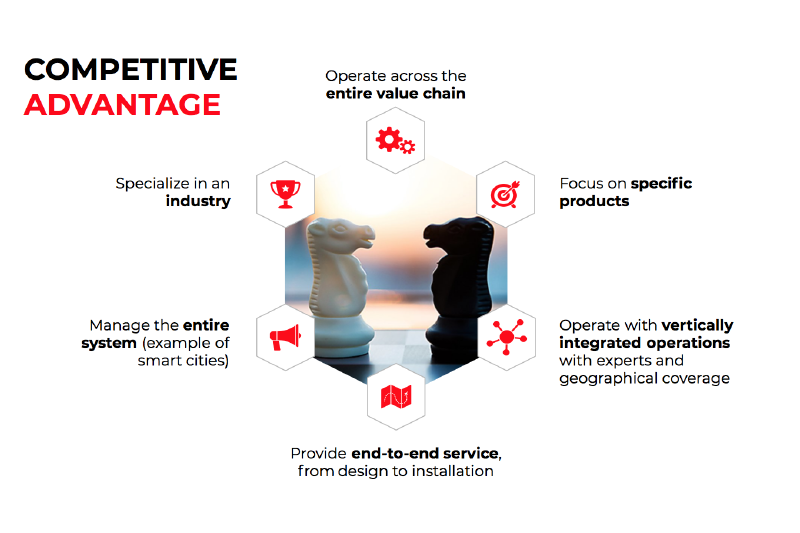

A brief analysis of the information gathered on competitors allowed us to synthesize their competitive advantage into 6 categories – see diagram above for more details.

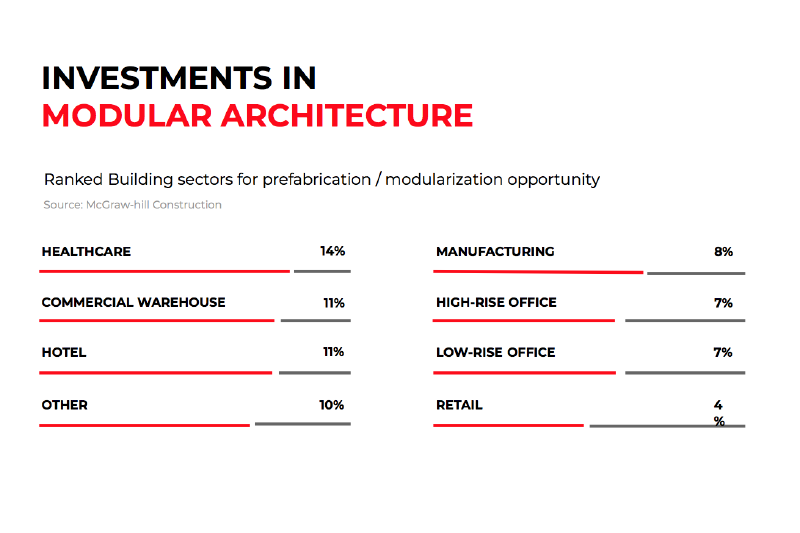

We scanned the different industries to understand where the current / future investments are; we also dug in to better understand what their needs are and how they are currently leveraging modular architecture.

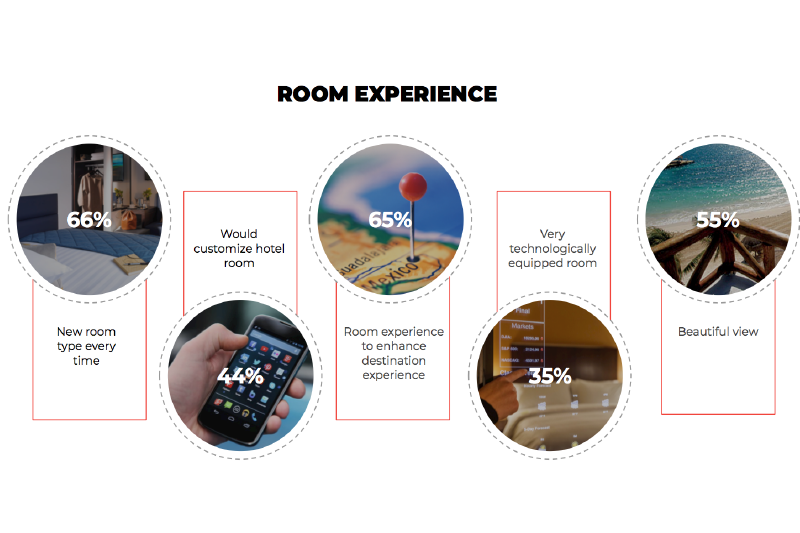

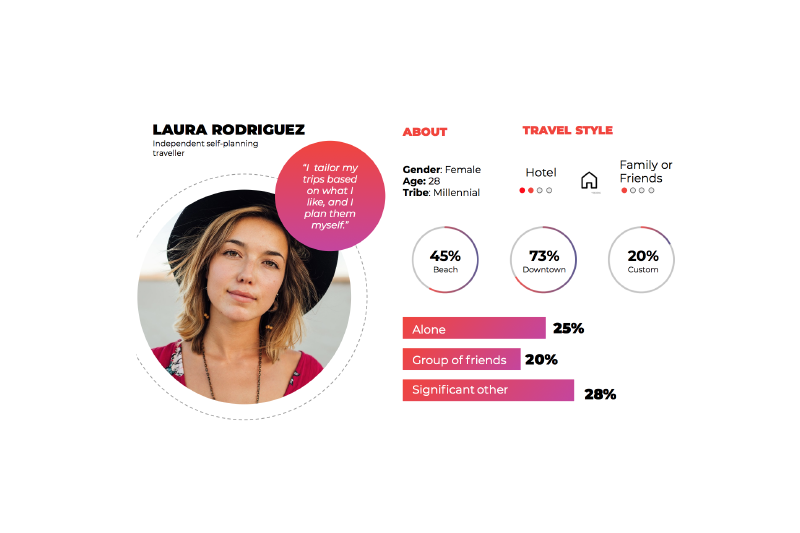

Our human-centred process led us to perform research in order to understand the needs of the end-customer. For this particular use case, our research focused on their needs for hotel / hospitality.

See diagram above for more information of room experience features sought by customers.

As modular architecture is already being used by key players in the hospitality industry, we dug other industries to see where the next opportunity could be. The three industries in which we saw a potential based on investment and need were:

- Healthcare – hospital and clinical units

- IT – Data Centers

- Oil&Gas / Mining – temporary camps during exploration and exploitation

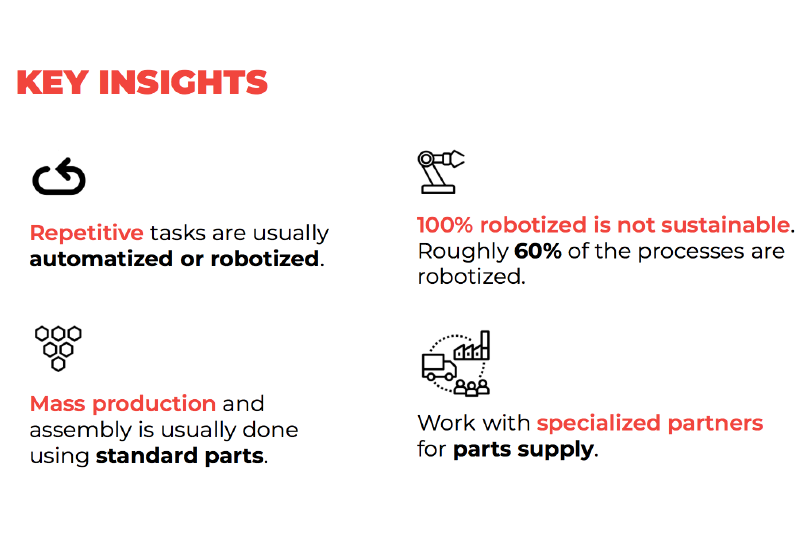

We interviewed some plant and process engineers to understand the process and intricacies behind mass manufacturing. Companies interviewed included the following companies: Linamar, Ford, Airbus, Bombardier, Pratt&Whitney, MDS Aero, Veguzti.

The insights informed the strategic advice given to our client with regards to mass manufacturing modular architecture.

Our design process

The client’s problem was to see how an open innovation platform could help them gain:

- Ideas for their innovation / growth portfolio

- Customer-data to create user-centric solutions

- Expertise from industry leaders for the mass manufacturing process

Given the disconnection between the client’s 2 asks, namely

#1: strategic plan for modular manufacturing company

#2: open innovation to connect different hotel chains and hotel investors

Our solution was to overlap the two requests: leveraging an open innovation platform to solve the challenges related to the design, mass manufacturing and distribution of the modular room.

… design an automated manufacturing plant for the production of modular architecture?

… create an open innovation platform to support the manufacturing process?

Depending on the industry to produce for, end-user research needs to be performed to understand the room amenities. In this example, we looked at the hotel industry and investigated different types of travellers from a wide range of age groups. The research insights are summarized in this persona.

The concept of Room 23 for industries is to design standard parts in order to mass produce. Different models of modular units can be built with the standard parts, similarly to lego structures. However, different combinations will result in different units which can be adapted to the needs of different industries – for example: a specialized hospital room, a mining camp, a hotel room etc.

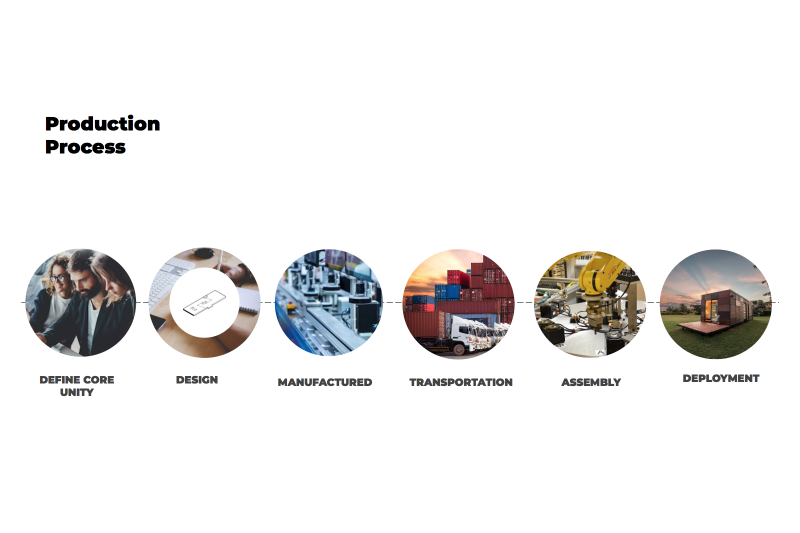

Based on the research insights gathered, a production process was designed for the client. Key points include:

- The “Core Unity” are the project owners; they will always include the client’s innovation team and their partner Architect. However, the 3rd partner will always be a leader in the industry for which the modular unit is produced for.

- The design, manufacture and assembly will be done in the client’s various manufacturing facilities.

- Transportation of the units and deployment will be performed with the assistance of key industry partners.

The business model was broken down to define key features of this new business line; this included: the process, network, customer engagement, service, profit model, the structure of the business in order to serve the different industries, the features to develop for the rooms.

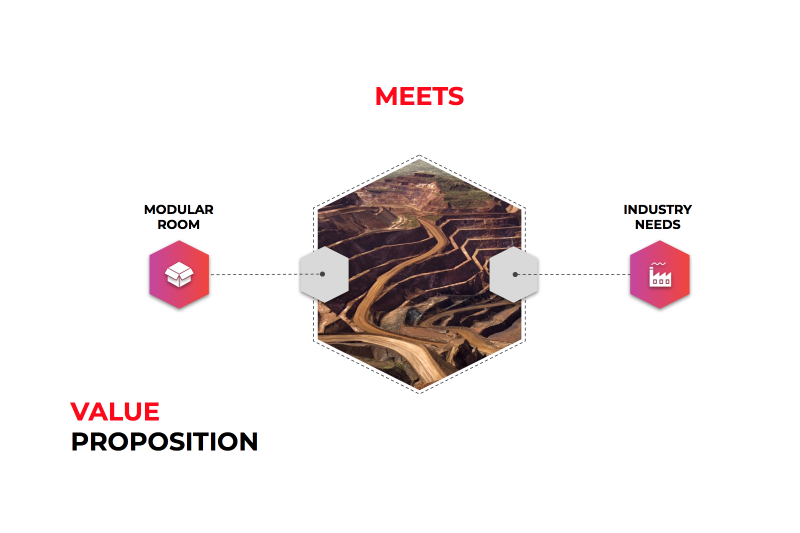

With the thought leadership of the industry partners, this new business unit will be able to identify the value proposition for clients in that industry – how do the modular rooms meet industry needs?

Namely:

– How are pains relieved for future potential customers?

– How is the modular room creating a gain for the future potential customers?

– How do the features of the room support the customers’ job requirements?

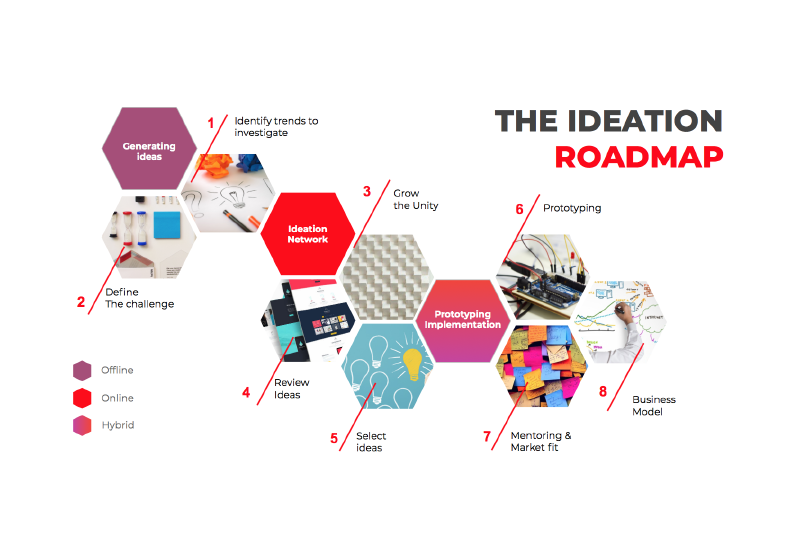

After a lot of research, analysis, benchmarking and assessing the needs of the open innovation platform required for co-creation of the modular units, one major conclusion was to have an open innovation that mixed both online and offline activities.

The open innovation process for ideation was mapped to take advantage of a hybrid process: some steps are offline (networking events, workshops etc.) while others are online (online social network, idea submission and filtering etc). We also incorporated a set of hybrid steps which would require a mix of online and offline activities.

See diagram above.

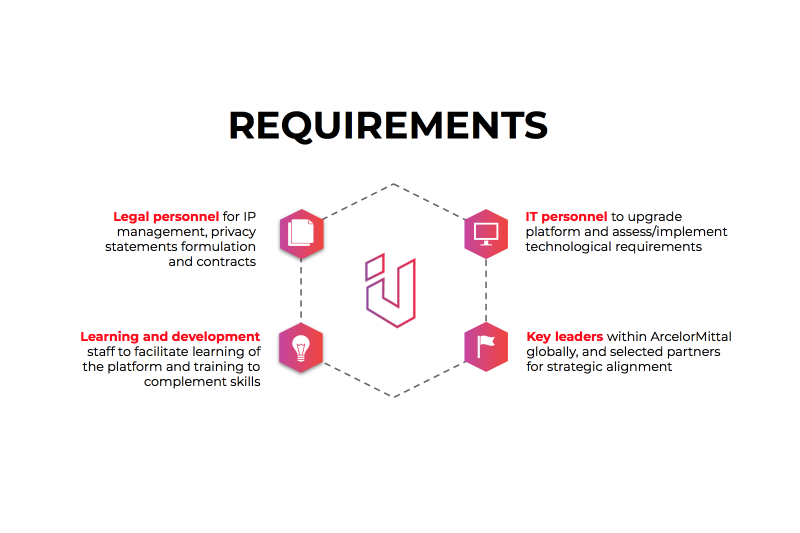

We analyzed all the requirements to run the open innovation platform and program, from an IT perspective, as well as from a human resource and legal/IP perspective.

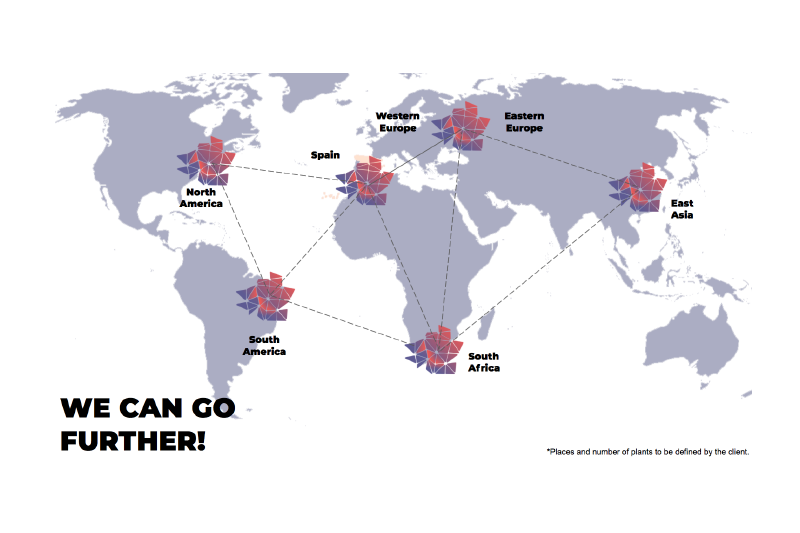

As a global company, we create a model that would be easily replicable for scalability. The system would depend on: where the client’s manufacturing plants lie and where potential clients for the modular rooms are located.

Deliverables

We created an implementation playbook with an executive summary of the project as well as all the detailed work performed. This includes but not limited to: our SWOT analysis, a blueprint of the open-innovation process / service, the UX of the digital portion of the open innovation platform, the sample 3 business models developed for the 3 industries of interest, roadmaps for prototyping the solution, and implementing it.

We created a landing page ready for the client to use. The objective is to test whether the “Room 23 for industries” is a desirable offering for their clients and partners.

Accessible via the QR code on the image above!

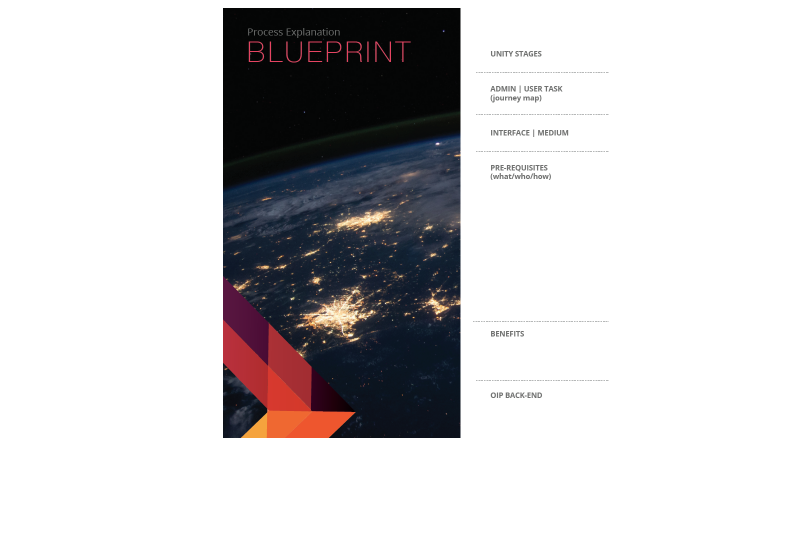

We created a very detailed service blueprint with journeys from the different potential users, the different media the users would interact with in the process, identified what resources should be in place for specific steps to operate smoothly, the “aha” moments for the user, as well as all back-end resources. For each activity in the journey, we also identified the KPIs to be used and detailed how to measure them.

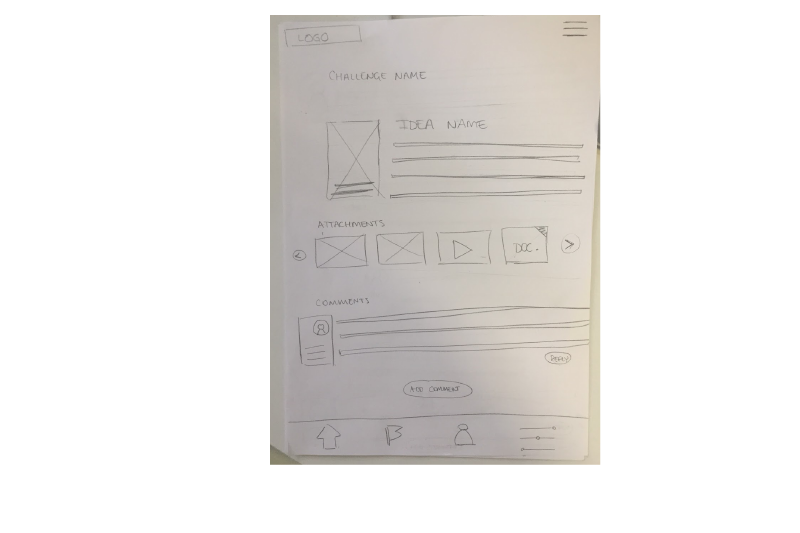

We designed the user flow, the information architecture for different users, and a hi-fidelity prototype of the online digital portion of the platform.

We began the process with

- Low-fi mockup-done done by hand as shown in the image above

- We then took pictures and created an interactive low-fi prototype using Marvel, for the first round of testing

- Finally, we created a high-fidelity version of the prototype using Sketch

- And performed a 2nd round of testing using Invision

We made a SWOT analysis to understand how this open-innovation platform would position the client in their new business area (modular architecture).

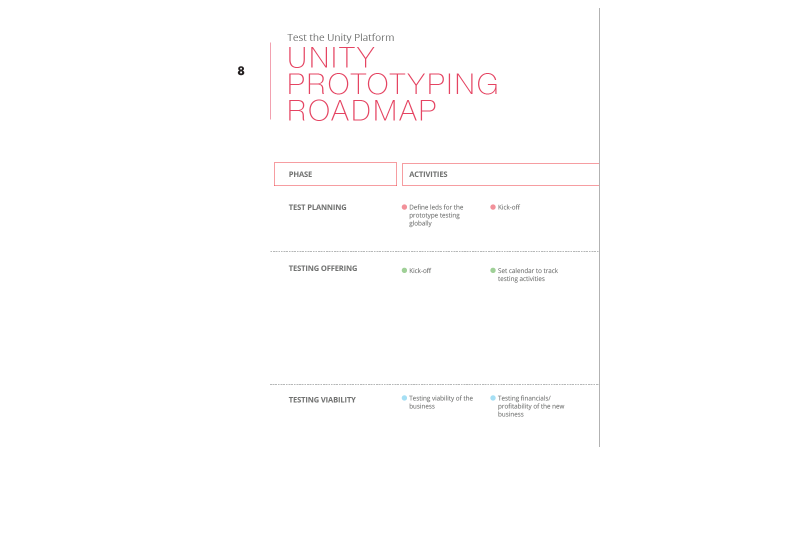

We created a detailed roadmap to guide the client in the next phase, step by step.

- The prototyping roadmap: since our project was in such a tight timeline, we were unable to prototype with the client’s existing partners; as such, we provided a landing page for them to prototype the value proposition of the new business.

- The implementation roadmap: assuming that there is interest in the new business, the implementation roadmap contained all the details to go ahead and implement our proposed solution.

Key learnings

Complex requirements to run an open innovation platform effectively

- Designing the optimal process

- Understanding different resources required to manage the open innovation process

- Complexity of the operational requirements for a frictionless (end-user) and efficient (employee/operations) open innovation system

- High cost based on resources required

Effective prototyping of a complex & costly solution

- Testing of a business model

- Testing of a value proposition

- Finding different prototyping methods to test the online / offline / hybrid nature of our solution

- Create a prototyping roadmap to test interest and impact

- Design the prototyping roadmap such that resource allocation require can be tested at a low cost –> small scale small projects

Parametric business design

- Designing a business model with constantly changing partners / stakeholders

- Creating a profit model adaptable to different industry needs

Use of new tools

- Business model canvas

- Value proposition canvas

- 10 types of innovation – innovation tactics

- Service Blueprint

- Video making (Adobe Premier)

- Sketch for hi-fi visual design

- Invision and Marvel for interaction design / prototyping

Other applied skills

- Design thinking process

- UX Design:

- Information architecture

- Interaction design with the design of user flows

- UI design – choice of visual elements, size, colors and placement on screen

- Storytelling & presentation

- Workshop facilitation

- Branding of the spin-off

Explore more projects on my portfolio!